How Aeroseal™ Works

The average home:

~ Has about 180 feet of ductwork

~ Accumulates over 40 pounds of dust each year

~ Leaks 20% of conditioned air

~ Wastes $300 a year in energy cost through leaky ducts

If every home in the United States sealed leaking ductwork:

~ Consumers would save over $5 billion in energy costs every year

~ It would be like taking 13 million cars off the road every year

Variations In Room Temperatures

Did you know that your ductwork is the most likely cause of this problem?

Leaks at elbows, fittings, and joints in your ductwork cause losses of conditioned air before it gets to your rooms. Sometimes poor duct design, inadequate insulation, careless initial installation, or damage from other construction trades, can cause ducts to perform poorly. In other cases, a duct can be so long that back pressure causes air flows to be too low, which in turn affects delivery temperatures. Rooms that receive low airflow and/or poor delivery temperatures are generally uncomfortable. Raising or lowering the thermostat to compensate means that other parts of your home will be overheated or overcooled.

Excess Dust? Getting Allergies at Home?

Your ductwork might be causing the problem. Leaks in return ducts pull in dust from dirty attics, basements, or crawl spaces. This polluted air can bypass the filter, be delivered to your furnace fan, then distributed into your supply ducts, and finally blown into the living area of your home.

Jett-Seal Inc. can diagnose whether your ductwork has significant flows through leaks, and then seal the small rips, separations and cracks that add up to cause that leakage. Aeroseal can improve your indoor air quality along with your allergies.

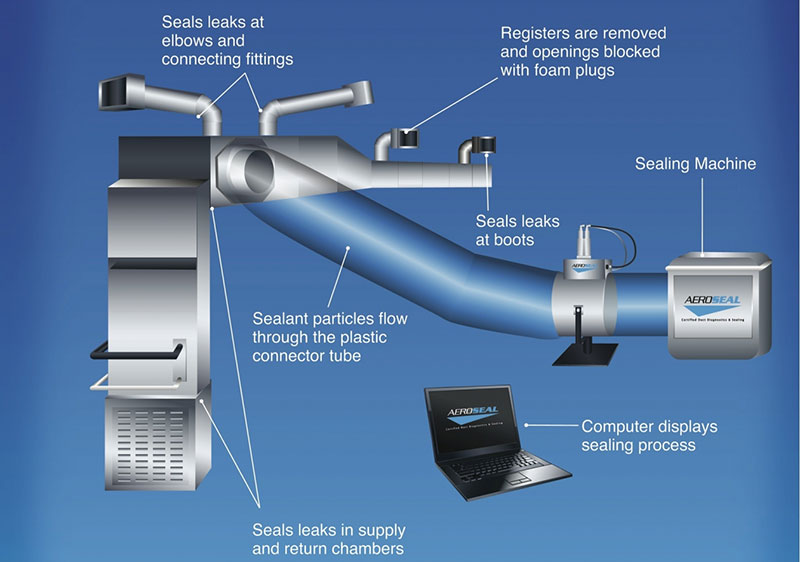

When the computerized Aeroseal process begins on your home or business, all room ceiling or floor registers are removed and foam plugs are installed in their place. An access hole is cut into the supply or return plenum and a temporary collar is then attached. The air conditioning coil, fan, and furnace are temporarily blocked with a foam plug so that the sealant particles produced by the machine will not find their way into the equipment. The Aeroseal injection machine is then connected to the duct system using a long flexible plastic tube.

The exclusive Aeroseal technology injects adhesive particles into the duct system. The adhesive attaches directly onto the edges of the holes, creating a seal without coating the ductwork. The results are verified and provided to you upon completion of sealing.

Seal your ductwork in 4 to 6 hours and you are on your way to energy savings and comfort improvement!

Jett-Seal Inc. uses Aeroseal technology to seal the ductwork from the inside out by using a UL tested and approved sealing material. It’s clean and safe.

“Our home has three units and Jett Seal analyzed all three. They measured leakage in all three systems and two had significant leaks. These units were installed in 1979 so it was time for some improvement. Our electric bills have already gone down — was it worth it? I’d do it again! Their system worked great and when they were done, they cleaned up until everything was spotless.”

Charlie C., Lake Hamilton

Jett-Seal is an official Aeroseal™ and Duct Armor® product dealer.